mrwalsh85 Wrote:

-------------------------------------------------------

> It was my understanding that piston centerlines

> should be aligned with the centerline of the

> driving axles. If the T12 was straightened out,

> and as such, higher than the CL of the driving

> axles, this could be problematic, correct? I could

> see some "waddling" of the locomotive occurring

> under power.

Herb Kelsey Wrote:

-------------------------------------------------------

> Right Mr. Walsh. Here is my assumption and, my

> not being a mechanical engineer means I AM

> assuming, but most locomotives have the piston on

> the same level as the center of the drivers. On

> the T-12's the center-line of the cylinders is

> raised above the center-line of the main driver's

> axle. This is possibly due to clearance problems

> for the 4-wheel lead truck. So to create four

> equal power stroke events per revolution I think

> the cylinders would be angled downward to align

> the piston rod with the main driver's center.

> Setting up the valves to get four equal strokes

> would seem to be difficult if the components

> weren't aligned.

It was nearly universal that locomotives with level cylinders rode with the piston rod centers 1” or 2” above the axle centers. IIRC, #20’s piston rods are around 5” above the axle centers, way more than any other locomotive I have run across. Nevertheless, this doesn't affect the valve timing as any of the YouTube videos of #20 in operation will attest.

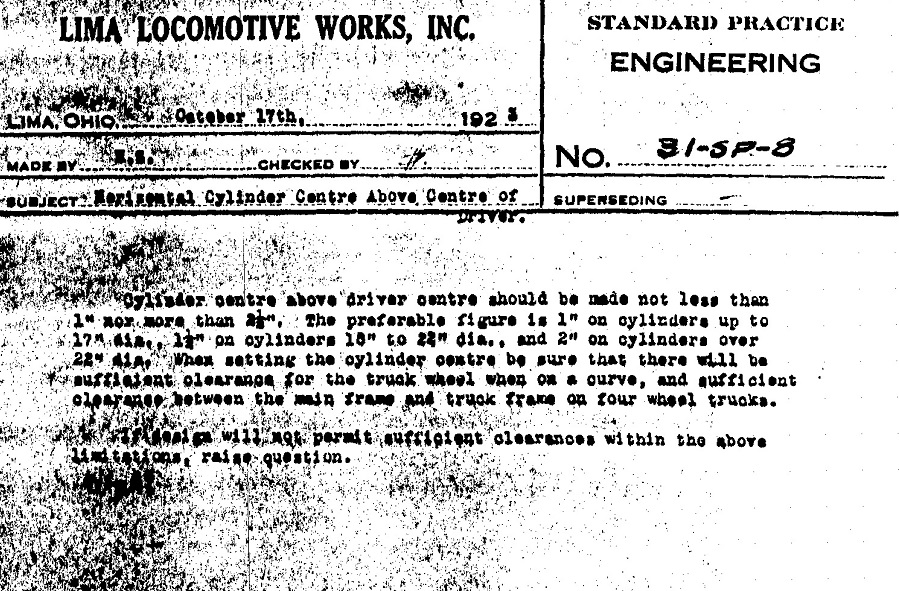

The builders were all very coy as to the reason behind this nearly universal practice, Lima giving the only clue, that it was tied to the diameter of the cylinders, but they don’t say why.

I agree with Johnson Barr, that it was done to compensate for the reduced thrust on the forward stroke due to the piston area taken up by the piston rod. How does raising the cylinder help? Here’s my opinion. By making the main rod closer to horizontal on the forward stroke, the vertical load on the crosshead is reduced compared to the back stroke, so the frictional drag on the crosshead is reduced compared to the back stroke. Less drag leaves more of the piston’s thrust available to pull on the crankpin.

An interesting side bar is that modern automobile engines sometimes have the cylinders offset in relation to the crankshaft in order to reduce the angularity of the connecting rods on the power stroke. Others have the wrist pin hole in the pistons offset to give the same effect.

I have never seen a detailed drawing of the engine unit for a Shay locomotive, but since they virtually all ran in reverse for 50% of their lives, I would bet $0.05 that their piston rod centers were in line with the crankshaft center.

The fly in the ointment of this theory is that SP’s cab forwards also have their piston rods about the usual 2” higher than the axle centers, even though they ran in reverse in normal operation. But like I say, the reason for this detail is missing in the builder’s standard practices, so it may have fallen through the cranks in the Baldwin design offices (or maybe SP just wanted more ground clearance under their cylinders).