Be warned - there is no such thing as a simple answer from me ....

The diesel-electric truck (or bogie if you prefer) evolved from the passenger car truck, which had been adapted to electric motors for trolleys. For GE and other builders of small diesel-electrics, it was most cost effective to fabricate (cut and weld) trucks because they could be constructed economically in small batches and the design easily modified as needed. The alternative was to use a cast steel steel design, which typically required new patterns for each design and use of an outside foundry.

For low speed service, a truck design with primary suspension was sufficient. These designs typically offered an equalizer arm running across the journals, with a solid bolster welded to the side frames transferring the weight on a couple nests of coil springs to the equalizers. This design, like freight car trucks, is fairly simple and offers enough vertical movement to allow them to traverse most track irregularities. For diesel locomotives equipped with switcher type trucks, the maximum speed, at least leading, is generally restricted to a 45 mph maximum speed. I've run EMD switchers on the BN mainline at 45 mph and it was not a smooth ride by any means.

Notice that most (real) passenger cars and cabooses have a more complicated truck suspension. The same applies to road diesels. A road (or passenger) truck typically has the coil springs providing vertical movement, but adds a secondary suspension system that offers lateral movement, which absorbs much of the lateral jolts and allows the engine (or car) to sway to the side as it enters or exits a curve. A common arrangement is for the bolster to be carried on leaf springs which allow the engine (or car) carried by the bolster some sprung lateral movement.

Variations of the the above truck was used on the 50/52/54 ton models, and is the general design use on most smaller GE designs before 1960. For 36" gauge plus, a wheelbase of 60" typically indicates one traction motor driving the second axle through a chain or siderods, a 82" wheelbase was common on the industrial line with two traction motors. Note that there are pairs of equalizers, both inside and outside of the sideframes. The bolster is solid, and there is no allowance for lateral motion beyond normal clearances and wear.

Now refer to the left photo Bruce posted in the previous post. This is the design that GE adopted circa 1958 which replaced the paired equalizers with single heavy outside equalizer across most model lines. In addition, instead of the springs being grouped they are now lined up in a row under the equalizer. I'm not sure how much cheaper it was to build this designs, but it is obvious that if it became necessary to replace a broken spring or worn equalizer that they could were more accessible. This was the design used by most of the early U6B units (which should include IRCA 802 and 803) and continued to be used until the end of small GE locomotive production.

Referring to the center photo in the previous post: This is referred by GE as a swing bolster rubber suspension truck. GE 70 tons for Canada and several large late orders for Brazil were equipped with General Steel Castings trucks instead of the standard GE fabricated truck. There could be two explanations for this: The GSC truck might have had secondary lateral suspension (unknown), or the customers preferred a cast truck due to cracked welds in fabricated trucks (cracked welds continue to be a problem in newer passenger fabricated European truck designs such as Amtrak's Acela.) GE apparently did not want to rely on or pay for an outside road truck, so developed their own design. The prototype of the GE swing bolster rubber suspension truck was first applied to first production U6B which was loaned to Lancaster & Chester while their 70 tons rotated back to GE for rebuilding. This unit was returned by L&C and appears to have had its odd prototype trucks replaced with standard trucks and resold to the Philippines. The production version of this was offered on the U5B and U8B as a road truck and most of the production to Brazil and South American customers received this truck.There appears to be some variations/modifications of this design.

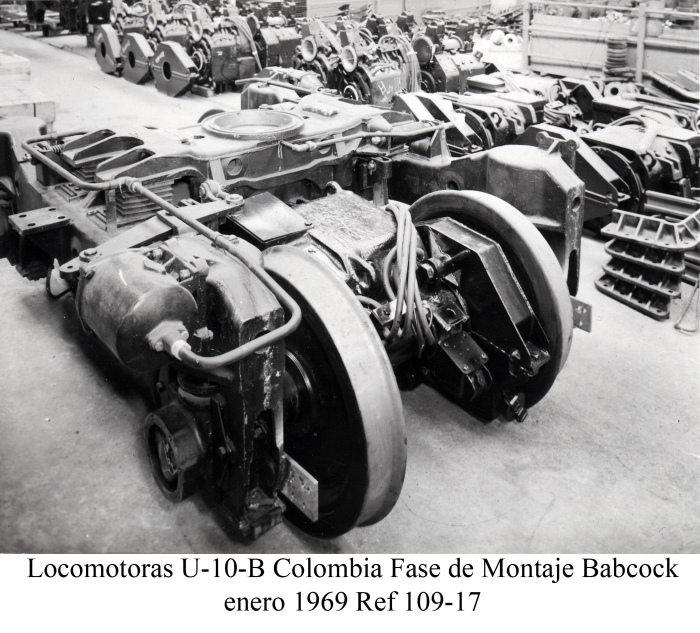

Referring to the photo on the right of the previous post: While a substantial number of the swing bolster rubber suspension trucks were applied to GE Cat powered Universal locomotives, there must have been some kind of production, cost or maintenance issue. About 1963 (with the Vietnam U8B orders) they disappeared being replaced by the cast floating bolster truck as the standard road truck (photo on right). This truck was made the standard truck for most subsequent small Universal production until the end, though the single outside equalizer truck continued to be offered as a lower cost option. In the photo below, you can see that the "H" shaped bolster sits on top of the truck frame on rubber pads. These pads are actually slightly angled inboard to center themselves, and are tall enough to provide some lateral motion or sway. GE lists some early three axle truck designs with equalizers as floating bolster, so apparently this arrangement was in use, but not obvious, on other designs. A similar design in both two and three axle designs were developed by GE for their domestic production. EMD developed their "Flexicoil" line using a similar theory, but uses tall coil springs instead of rubber packs to allow lateral movement. Shock absorbers were added on all later production. The former small Universal cast floating bolster has reappeared in a heavier design on the large B+B-B+B narrow gauge GE's and various used converted locomotives.

Confused?

Dan

Edited 2 time(s). Last edit at 09/13/2016 03:27PM by Dan Robirds.